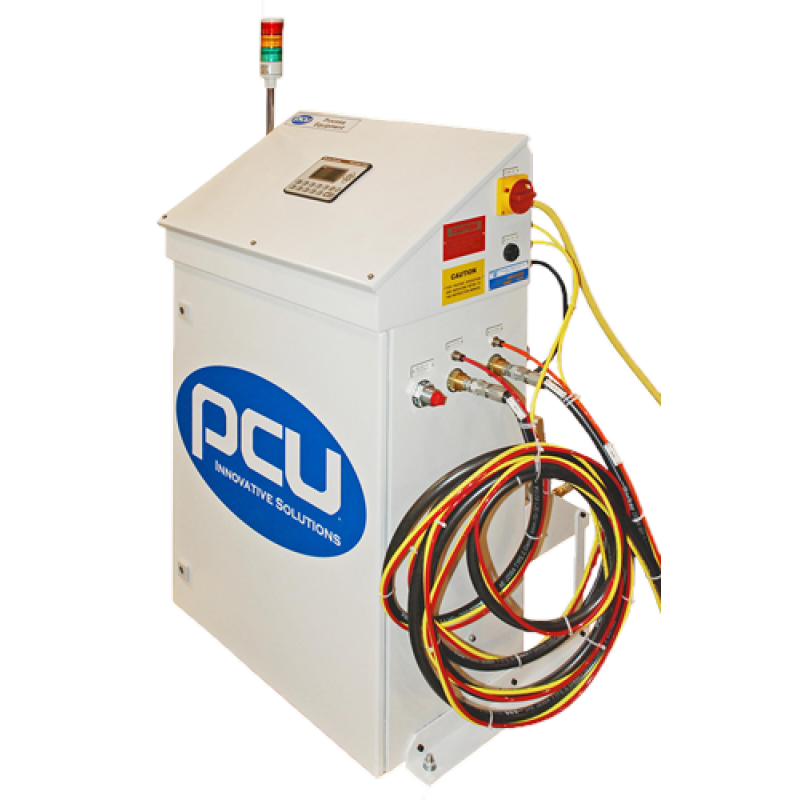

The PCU combination Proof Test and Tracer Gas Charge Stand is an efficient way to proof test and administer tracer gas into the unit to be leak tested. This stand is complete with tool and hose assembly (nominally eight feet long). It is intended that this stand will be located next to an assembly line and ahead of the leak test area. The tool terminates with a PCU Series 250 coupler.

The operator connects the PCU tube quick connect (TQC) couplers and process hoses then presses the start cycle pushbutton. The product is filled with the proof test gas. If the product fails to achieve the required proof test pressure the product is rejected (red light) and will not be filled with helium. After the product passes the proof test phase of the cycle the proof test gas is exhausted from the product into the atmosphere. The product is evacuated to remove air prior to the product being filled with the tracer gas. After the product is verified that it is at pressure the machine will indicate (yellow light) to the operator to begin manual sniffing. The operator manually sniffs all joints using a tracer gas leak detector. If a leak is detected a red light will illuminate. A green light will illuminate signaling an acceptable test. After all joints have been sniffed the operator depresses the tracer gas recovery pushbutton. The tracer gas will be recovered from the product by the plant wide tracer gas system; otherwise the tracer gas will be vented to atmosphere. The operator removes the process hoses and PCU TQC couplers. The operator finally installs the rubber plug, inserts the hypodermic needle into the rubber plug and fills the product with a low pressure shipping charge.

Features and Options

-

- Fully automatic process

-

- Operator Interface Terminal

-

- Customizable process and cycle options

-

- Multiple selection criteria

-

- Continuous monitoring of parameters

-

- Automatic clamp tooling

-

- Rapid flow precision tooling

-

- High-speed fill rates

-

- Barcode reader product identification

-

- Fault indicators