Features and Options

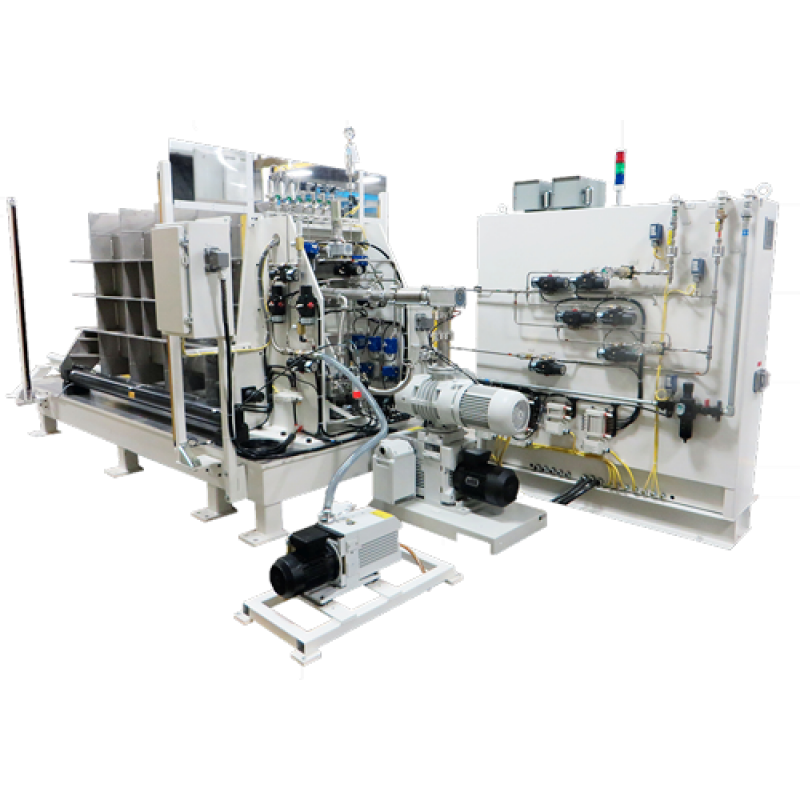

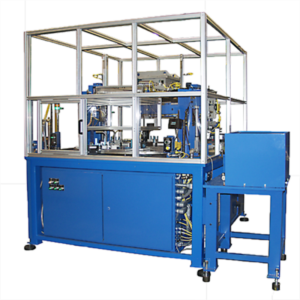

•Two-stage rotary vane roughing pump with blower

•Integrated Inficon LDS 2000 mass spectrometer

•Onboard NIST traceable calibration verification capable

•Integral test verification with every cycle

•Multiple fault indicators

•Allen-Bradley Panel View

•Allen-Bradley Micro Logix 1500

•Data mining w/printer capable

•Optional power requirements available

•Optional chamber configurations available

•Capable of detecting leaks to 1×10-5 atm cc/sec*

•Total test time less then 2 minutes (Dependent on part configuration and test time)