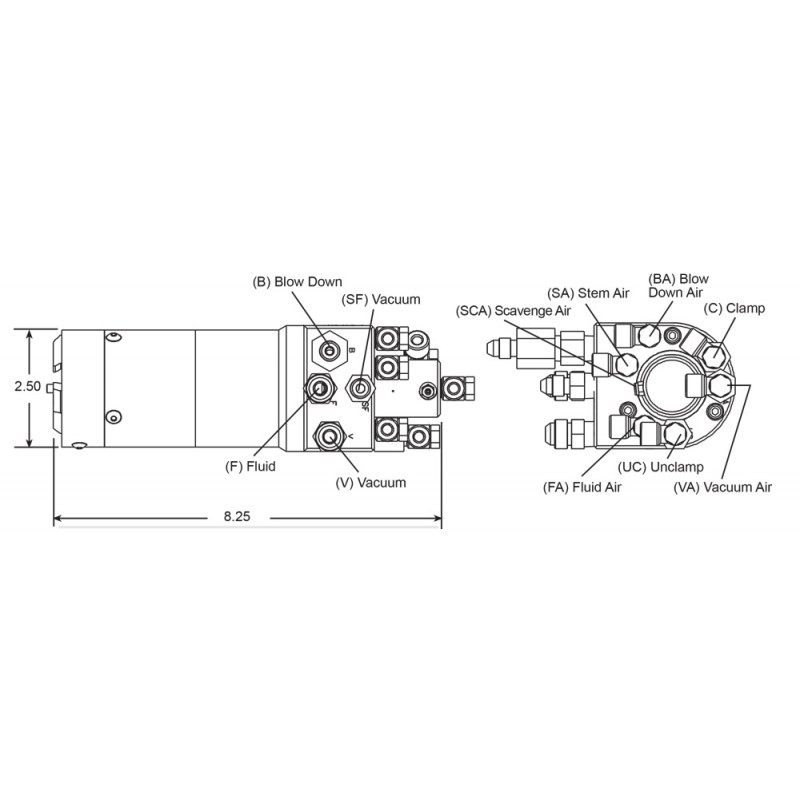

The 114 fill tool connects to the brake master cylinder reservoir for evacuating and filling the brake system. This series of tools can attach to most common brake fill necks and can be customized for other applications. The tool can be semi-automatic or fully automatic when attached to a tool presentation arm. The tool allows for minimum fluid loss, has a dry evacuation circuit, is air operated and light weight. Comes in a variety of styles including straight manifold, 90 degree manifold or an optional handle with pushbuttons model.

Features

- Simple Attachment

- Minimum Fluid Loss

- Semi-Automatic or Automatic Operation

- High Vacuum Flow Rates

- Easy Maintenance

- Economical

Specifications

- Factory Air Supply: 70 psig/4.9 (min.) kg/cm²

- Air Port Fitting: 1/4″ Dia. One Touch Connectors

- Weight: 4.25 lb/2 kg

- Fluid: Brake Fluid

- Fluid & Vacuum Port Fitting: 3/8″ JIC

- Scavenge & Blowdown Port Fitting: 1/4″ JIC

- Fluid or Vacuum or Air Blowdown: 0.82 Cv Typical

- Maximum Fluid Pressure: 150 psig

- Typ Flow Rates:

- 0.2 L/sec @ 70 psig

- 0.24 L/sec @ 90 psig

Technical Data

- Designed for two different scavenge levels.

- Scavenge flow path is independent of fluid or vacuum circuit.

- Tool designed with secondary shutoff value for dripless operation.

- Tools can be used with PCU tool presentation arms for manual connect – pick and place – semi-auto attachment to vehicle reservoirs.

- Fits large and small brake necks.

- Internal porting for higher flow rate

- Tool designs for volume or pressure fill.

- Tools are built with spring returns on the valve ports for fail-safe operation during power loss.

- All phases of evacuation and fill cycle internal to tool are automatically controlled by the evacuate and fill machine.

- Tools are compatible for operation with programmable logic, relay, or computer based control systems.

- A robust design and durable construction work well in a constant use production environment.

- Aluminum and stainless steel construction are used to minimize weight and eliminate corrosion.

- Tool designed with independent blowdown circuit for fluid circuit clean out.

- Optional straight or 90° manifolds.