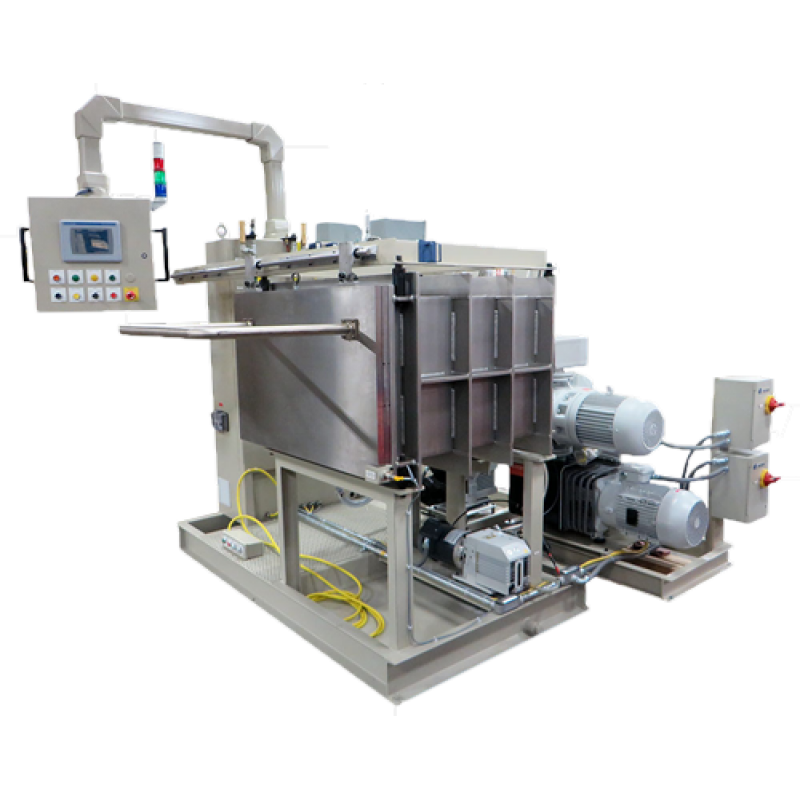

The Helium Mass Spectrometer Leak Detection System is used to identify both large (gross) and small leaks in a product. The system pressurizes a product with dry air and then completes a gross leak check to determine if a large leak exists. The machine checks for gross leaks using a pressure decay method during which the product is pressurized to 350 PSIA. The machine then isolates the pressure source and monitors the pressure in the product for five seconds. If the pressure decays more than 20 PSIA, the machine will abort the cycle and activate an alarm to inform the operator that the product has a gross leak. If the gross leak check cycle passes, the machine will evacuate the product and then pressurize it with helium to a pressure of 150 PSIA. The machine will then evacuate the surrounding chamber and perform a helium leak check by monitoring the chamber area using an LDS3000 Modular Leak Detector (manufactured by INFICON). If the product passes the helium leak check, the system will indicate a successful test. If the product fails, the system will move to Standby mode and allow the operator to manually check for leaks using an on-board sniffer. At the end of the cycle, the Operator Interface Terminal (OIT) will display the cycle data.